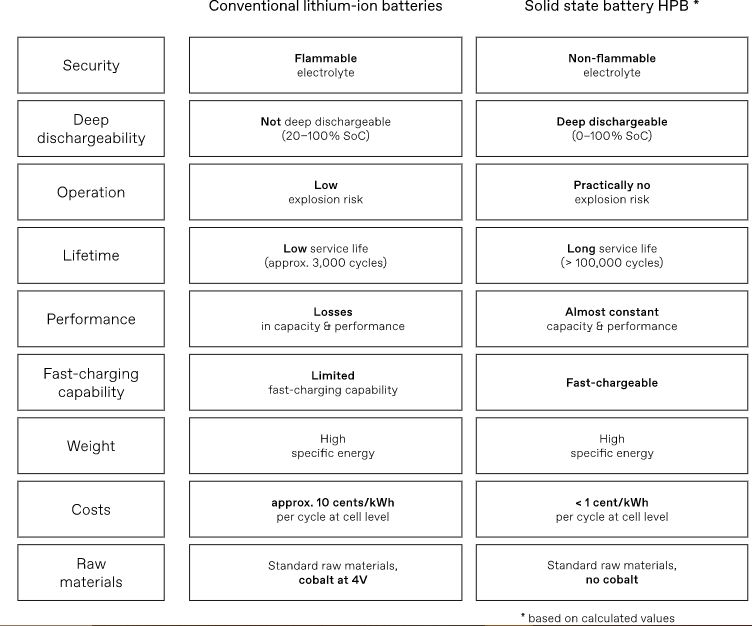

Quantumscape announced in late December it had delivered samples to automotive partners for testing, a significant milestone on the road to getting solid-state batteries into cars. The company has a deal with Volkswagen that could put its batteries in cars by 2025.īut completely reinventing batteries has proved difficult, and lithium-metal batteries have seen concerns about degradation over time, as well as manufacturing challenges. Quantumscape, for one, is focused on that technology and raised hundreds of millions in funding before going public in 2020. Solid-state batteries can use a wide range of chemistries, but a leading candidate for commercialization uses lithium metal. And because some solvents used in electrolytes can be flammable, proponents of solid-state batteries say they improve safety by cutting fire risk. Solid-state batteries could also move charge around faster, meaning shorter charging times. This swap unlocks possibilities that pack more energy into a smaller space, potentially improving the range of electric vehicles. Lithium-ion batteries and related chemistries use a liquid electrolyte that shuttles charge around solid-state batteries replace this liquid with ceramics or other solid materials. One advance to keep an eye on this year is in so-called solid-state batteries. Some dramatically different approaches to EV batteries could see progress in 2023, though they will likely take longer to make a commercial impact. Visit our dedicated battery raw materials page to discover more insights on the factors at play in the industry in 2022 and beyond.In the midst of the soaring demand for EVs and renewable power and an explosion in battery development, one thing is certain: batteries will play a key role in the transition to renewable energy. Fastmarkets’ battery manufacturing cost modeller, Muthu Krishna, recently wrote an article exploring why this has caused an increased interest in LFP-powered electric vehicles. The sharp rise in battery raw material prices has amplified the cost difference between nickel-based CAMs and LFP, increasing interest in LFP-powered EVs. Read more about why the EV battery chemistry debate is complicated for the industry

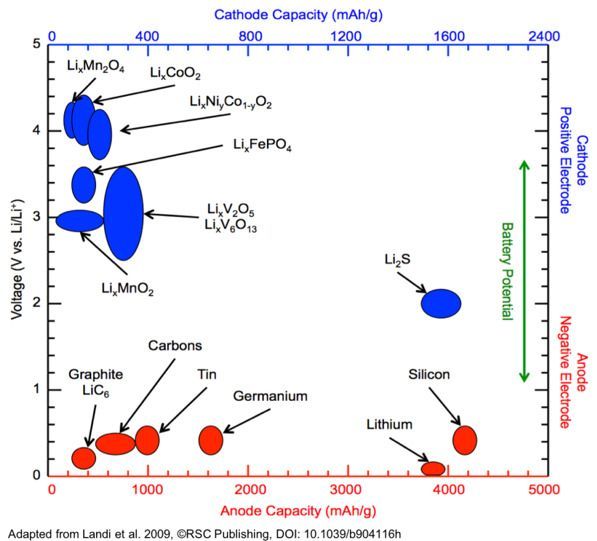

Solid-state batteries are so far from commercialization and are filled with challenges. What are the biggest advantages of solid-state batteries? To utilize the incredible capacity of lithium metal, you need to have a positive electrode material that does not contain lithium. You only want the lithium content on one side of the cell so it’s a balanced system. In our lithium-ion battery, the lithium content is in the positive electrode or the cathode.

Lithium metal is also a complete paradigm shift from what we have today.

For example, lithium metal batteries can be made into a much larger format, you could power an EV with a hundred single cells rather than the thousands and thousands that are used in today’s lithium-ion battery cars. What was a simple design and originally meant to power a handheld electronic device has now been pushed to its absolute maximum limitation. A lithium metal battery has up to ten times the capacity of a lithium-ion graphite anode. Today, we have one predominant battery technology that is lithium-ion. Lithium metal batteries differ from other batteries required for the energy transition in myriad ways. How do lithium metal batteries differ from other batteries used for energy transition?

0 kommentar(er)

0 kommentar(er)